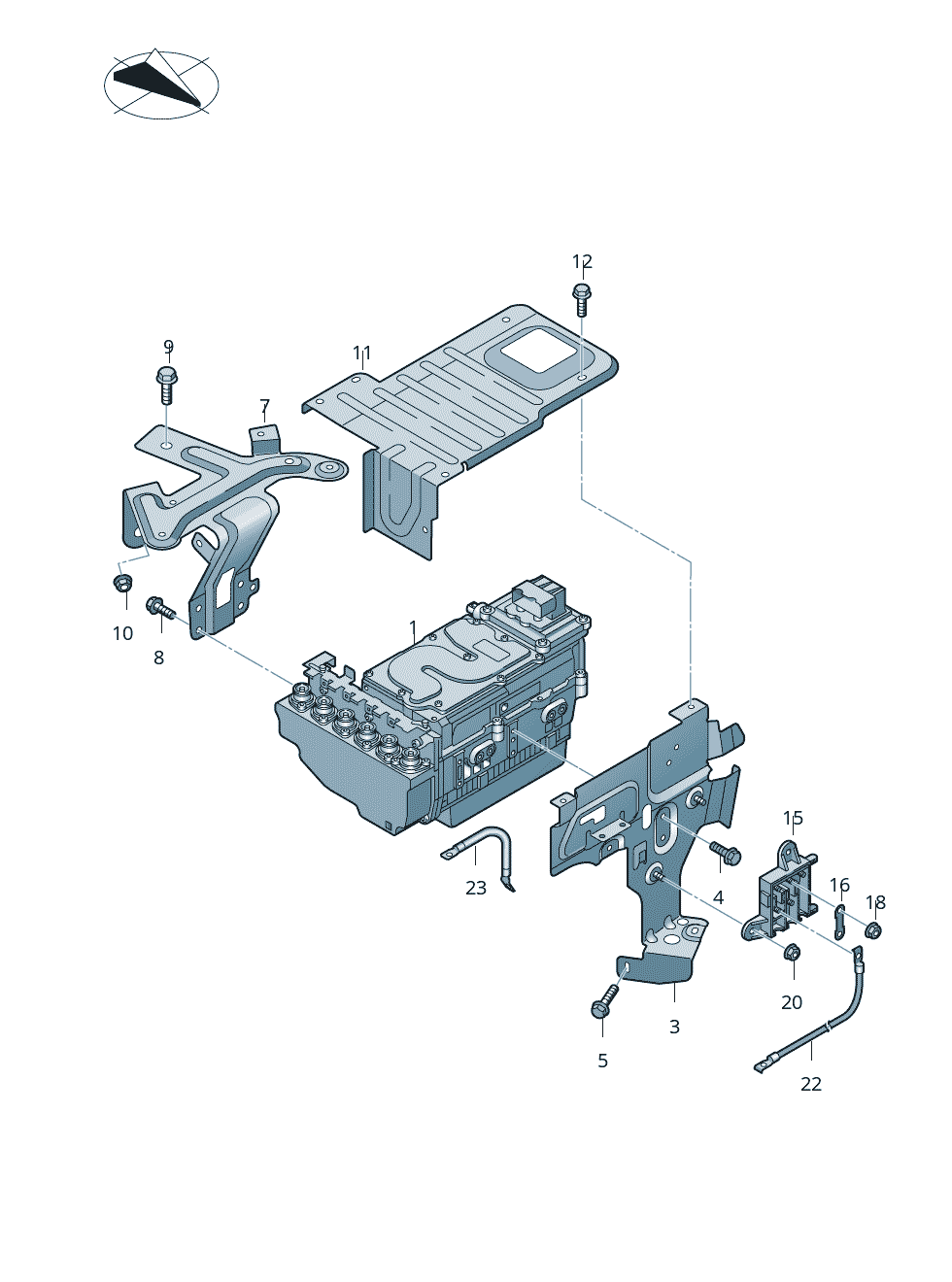

4G0907080, Power And Control Electronics-For Electric Drive

$8,335.62

This Power and Control Electronics Module is a high-quality, genuine VAG part specifically designed for Audi and compatible Volkswagen Group models. Engineered for exceptional performance, it is a key component of the power electronics system in select vehicles.

Product Details:

- OEM Part Number: 4G0907080 (updated to 4G0907080A as of March 1, 2013)

- Compatibility: Fits 12 Volkswagen Group models sold globally, including markets in Brazil, Mexico, Argentina, the USA, South Africa, and more (2011–2014).

- Reliability: Designed to ensure optimal performance and long-lasting durability.

Key Features:

- Genuine OEM quality for reliable operation.

- Worldwide compatibility across multiple vehicle models.

- Backed by a 6-month refund guarantee for peace of mind.

Shipping Information:

We ship worldwide with delivery within 10–20 days, ensuring you receive your part quickly and efficiently, no matter where you are.

Choose this module for unmatched quality, performance, and global accessibility. Perfect for ensuring your electric drive system operates at its peak.

Technical Details

| Brand | VAG |

| OEM number | 4G0907080 |

| First year of use | 2011 |

| Last year of use | 2014 |

| Part group | EAC (power electronics) |

| Dimension | 23 x 33 x 20 |

Description

Introduction to Power and Control Electronics

Power and control electronics are integral components of electric drive systems, which have seen significant advancements and applications in both modern electric vehicles and various industrial sectors. The evolution of these technologies has brought about considerable improvements in energy efficiency, performance, and overall system reliability. Understanding power electronics entails recognizing how they convert and manage electrical energy to drive motors and other systems effectively.

In electric vehicles, power electronics play a pivotal role in managing the energy flow from the battery to the electric motor. This involves converting direct current (DC) from the battery to alternating current (AC) for the motor, allowing efficient operation across various speed ranges. Moreover, regenerative braking systems are utilized to convert kinetic energy back into electrical energy, subsequently recharging the battery and enhancing the overall efficiency of the vehicle.

Key components of power and control electronics include inverters, converters, and controllers. Inverters are crucial for converting DC to AC while maintaining the stability of output voltage and frequency, which directly impacts motor performance. Voltage converters facilitate the adjustment of voltage levels to suit different operational requirements, ensuring that all system components receive optimal power levels. Controllers, on the other hand, are responsible for regulating the performance of these components, making real-time adjustments to maintain desired operational parameters.

In industrial applications, power and control electronics are utilized in various machinery and automated processes, including conveyor systems and robotics. These technologies not only improve energy efficiency by optimizing power usage but also enhance the reliability and longevity of industrial machinery. Overall, power and control electronics are fundamental in driving the advancements seen in electric drive systems, significantly contributing to both energy savings and performance enhancements across a wide range of applications.

The 4G0907080 Component Explained

The 4G0907080 component plays a crucial role in the realm of power and control electronics, particularly tailored for electric drive systems. This sophisticated element is engineered to facilitate efficient energy conversion and management, ensuring optimal performance in various applications. With a voltage rating of up to 250V and a current handling capability of 90A, the 4G0907080 stands out in its category, promising reliability and stability under varying operational demands.

Key features of the 4G0907080 include advanced thermal management properties, allowing it to operate effectively even in high-temperature environments. Its compact design is conducive to integration in tight spaces typical in electric vehicle and industrial equipment layouts, emphasizing its versatility. Furthermore, the component is designed with high switching frequency capabilities, making it suitable for applications requiring rapid response times.

When comparing the 4G0907080 with similar components in the market, it often demonstrates superior performance in terms of energy efficiency and thermal performance. While alternatives may offer similar specifications, the 4G0907080’s robust design grants it an advantage in scenarios where durability is paramount, such as in electric traction systems and renewable energy applications like solar inverters.

Optimal use cases for the 4G0907080 extend to electric vehicles, where it is integral to the inverter systems. Its ability to handle varying load conditions makes it ideal for applications that require adaptive responses to fluctuating energy demands. Additionally, its application extends to industrial automation processes where precise control over electric drives is essential for operational efficiency.

In summary, the 4G0907080 component not only embodies advanced technology but also serves a fundamental purpose in enhancing the functionality of electric drive systems, offering significant advantages over comparable components in the sector.

Design Considerations for Electric Drive Systems

The design of electric drive systems necessitates a thorough consideration of various factors to ensure optimal performance and reliability of power and control electronics. One of the key aspects is thermal management, as excessive heat generation can lead to component failure and reduced lifespan. Engineers must incorporate effective heat dissipation techniques such as heatsinks, fans, or liquid cooling systems to maintain temperatures within safe operating limits. Proper thermal management not only improves reliability but also enhances the overall efficiency of the electric drive system.

Electrical efficiency is another critical consideration in the design of power and control electronics. The efficiency of electrical components directly influences the system’s energy consumption and operational costs. Therefore, selecting high-efficiency components and optimizing circuit designs can significantly reduce energy losses. In addition, employing advanced control algorithms can further enhance efficiency by adapting the drive system’s operation to varying load conditions, ensuring that the system operates at its best performance points.

Compatibility with existing systems is also a vital factor when designing electric drive systems. Many applications may require integration with legacy systems, which can pose challenges in terms of communication protocols and electrical standards. Engineers should conduct assessments to identify potential compatibility issues and ensure that the new technology aligns with the prerequisites of existing infrastructure. This awareness can mitigate integration risks and promote a smoother transition to modern electric drive systems.

The selection of components plays a significant role in the overall performance of electric drive systems. It is essential to consider not only the technical specifications but also the long-term implications of component selection, such as availability, cost, and reliability. By carefully evaluating component options and their interactions within the system, designers can optimize the performance and durability of electric drive systems. These design considerations collectively contribute to developing robust, efficient, and reliable electric drive systems that meet the growing demands of modern applications.

Challenges and Solutions in Power Electronics for Electric Drives

Power electronics play a crucial role in electric drive systems, managing the power flow between the energy source and the electric motor. However, several challenges must be addressed to ensure the efficient and reliable operation of these systems. One of the most significant concerns is electromagnetic interference (EMI), which can disrupt the function of electronic components and jeopardize overall system integrity. EMI typically arises from high-frequency switching activities within power converters, impacting not only performance but also compliance with regulatory standards.

To mitigate EMI issues, designers often implement shielded cables, filters, and proper grounding techniques. Additionally, advancements in semiconductor technology, such as the development of wide bandgap (WBG) materials, can contribute to reducing EMI emissions through faster switching capabilities with lower losses. This innovation facilitates the design of systems with reduced electromagnetic noise, leading to improved system reliability.

Another challenge in power electronics for electric drives is thermal management. The heat generated by electronic components during operation can affect performance and reduce component lifespan. Excessive heat may lead to overheating, resulting in potential failure of the power electronics. A common solution to this problem is enhancing cooling systems, which can involve the use of heat sinks, forced convection, or liquid cooling solutions, depending on the system’s requirements.

Furthermore, manufacturers are increasingly focusing on improving the thermal performance of components through advanced materials and designs that enhance heat dissipation. This has been complemented by the utilization of smart thermal management systems that actively monitor and control the temperature, ensuring optimal operating conditions.

Lastly, the lifespan of power electronics components is a significant concern, as the reliability of electric drive systems is directly linked to their durability. To counteract premature component degradation, researchers are consistently exploring materials that resist aging due to thermal and electrical stresses, coupled with implementing robust design practices that prioritize longevity.

By addressing these challenges—electromagnetic interference, thermal management, and component lifespan—through innovative solutions and advancements in technology, the efficiency and reliability of power electronics in electric drive systems are significantly enhanced.

Future Trends in Electric Drive Technology

The field of electric drive technology is rapidly evolving, driven by the need for more efficient, reliable, and sustainable power solutions. One of the most significant trends in this domain is the adoption of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN). These advanced materials exhibit superior properties that allow for higher voltage operation, improved thermal performance, and reduced energy losses compared to traditional silicon-based components. As the manufacturing costs decrease and reliability increases, it is expected that wide bandgap semiconductors will play a critical role in enhancing the performance of electric drive systems.

Additionally, advancements in software control algorithms are poised to revolutionize the management of electric drives. With the increasing complexity of electric systems, sophisticated algorithms will enable more refined control strategies that optimize efficiency and performance across various operating conditions. Techniques such as model predictive control and artificial intelligence-based approaches promise to enhance system responsiveness and adaptability, thereby improving overall drive capabilities. This shift towards data-driven solutions underscores the importance of software innovation in the realm of power and control electronics.

The integration of renewable energy sources presents another significant trend shaping the future of electric drive systems. As industries and consumers alike push towards sustainability, electric drives must not only operate efficiently but also integrate seamlessly with solar, wind, and other renewable energy technologies. This trend necessitates the development of smart grid solutions and energy management systems to facilitate the dynamic interaction between electric drives and renewable energy sources. Such innovations will ensure that electric vehicles and other drive systems remain resilient and effective in the face of increasing energy demands and environmental considerations.

As we look forward, it is clear that the future of electric drive technology will be characterized by heightened efficiency, versatility, and sustainability, highlighting the importance of ongoing research and development in this dynamic field.

Reviews

There are no reviews yet.